Decades of combined experience in product development has helped us hone our ability to meet the needs as a medical device design and development partner and premier manufacturer.

We understand what you want from your product performance and when you need it to make your goals. We have developed several key areas that we focus on as a company to help provide the best results and experiences for all our customers.

These are the core values of our business:

We pride ourselves in fueling fast, efficient, and accurate product iteration. It’s not uncommon for us to produce parts before other companies have produced a quote.

Often our customers just need a prototype to obtain more information or funding. We help communicate concepts, prove out theories, refine ideas, and provide the product to help the project move forward.

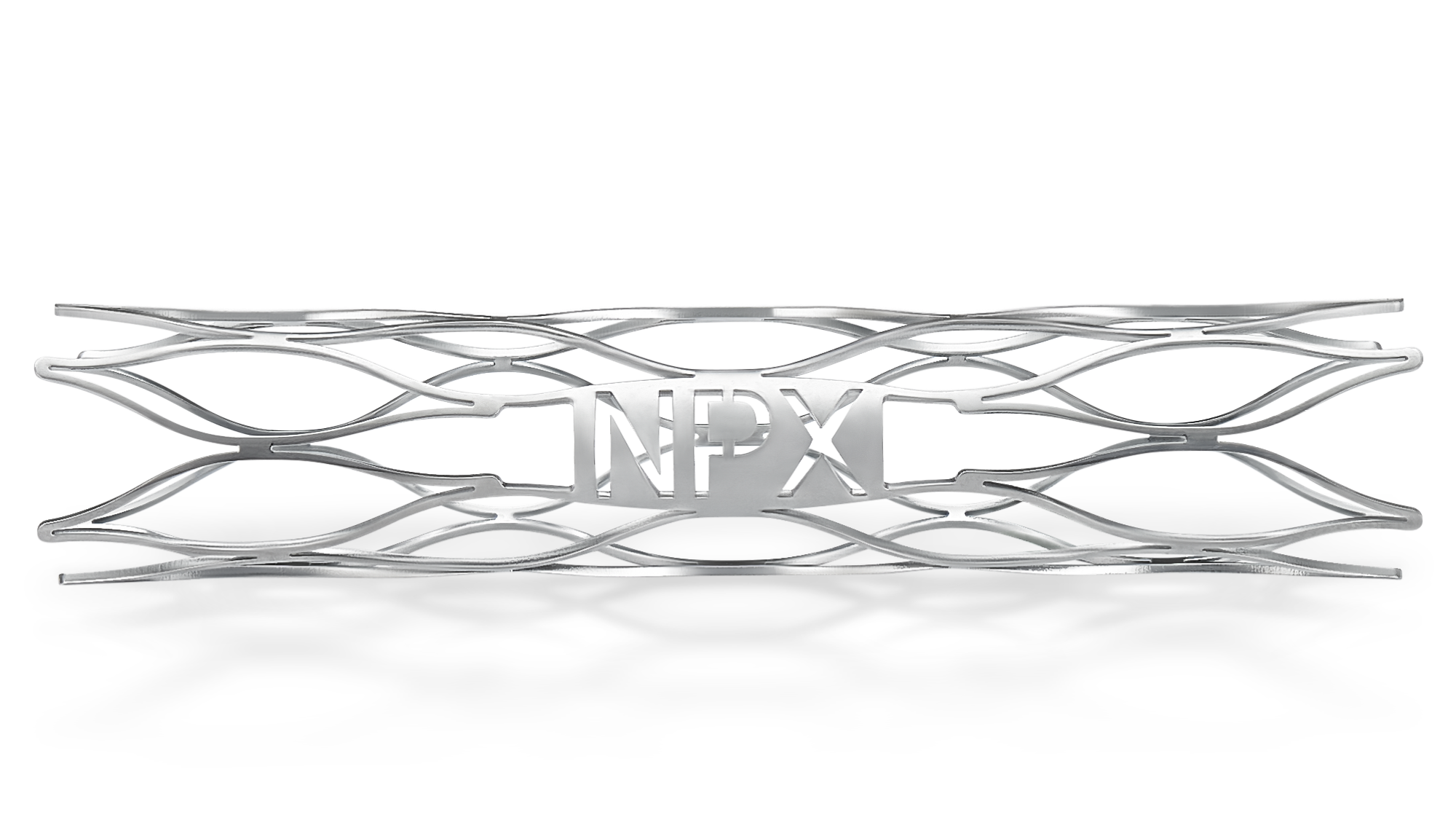

NPX excels when the stakes are high and lead times need to be kept to a minimum.

Our customers come in many different sizes and from many different places in their respective product development journeys. We have the opportunity to serve a wide array of customers including individuals who have only just started by jotting down thoughts on a napkin, all the way to large companies with fully developed product portfolios.

NPX’s vast medical device experience and expert engineering horsepower allow us to quickly add value to every stage of the project. With experience from helping to develop hundreds of successfully commercialized products, NPX is ready to help our customers all the way from inception through to commercialization.

NPX is your fastest quick turn source and best production partner.

At NPX we have thoughtfully structured our approach so that we always have excess capacity, which yields the shortest of lead times. We have a unique approach in which we have purchased machines ahead of the business in anticipation of what our customers might require. This allows us at any point in time to begin working on an order immediately. We strive to maintain that scenario at all times in all services so that we can commit to as short as a 3-5 day turnaround.

When we get into big production orders, we purchase dedicated machines specifically for those jobs–not relying on the same resources that we’re using for the development business.

R&D and Startup Medical Device Companies

We have always focused on medical devices–for over 30 years. We have extensive experience in most fields of medical devices; including but not limited to:

- Cardiovascular

- Cardiac surgery

- Gastroenterology

- Gynecology

- Interventional radiology

- Neurovascular

- Orthopedics

- Otolaryngology

- Thoracic surgery

- Vascular surgery

- Urology

The startup medical device companies often have such great appeal with all of the excitement, and vision, and pursuit of exciting new opportunities, and we find ourselves working with them often.

We tend to work well in small groups and then grow them with the needs of the customer. NPX is really created to serve that early R&D function, rapid prototyping–making sure that our customers can iterate, pivot, iterate, and ultimately find their way with us and do so very quickly–not having excessive gaps between iterations.

Agility is a key strategy for NPX.

Taking On Institutional Realities

In the medical device industry, it is commonplace for small companies to be priced out of the market almost immediately during an initial iteration.

When some large contract manufacturing companies won’t consider your project unless you are willing to come to the table with a considerable project minimum, it is very difficult to get any traction. Not to mention, these same companies want minimum orders for every subsequent iteration. Further, the lead times that the large contract manufacturers tend to offer are incredibly long–six months in some cases. This reality can be incredibly frustrating, and we don’t think that’s the way it should be, nor needs to be.

We offer engineering consulting and we do it on a time and materials basis reducing our customer’s tendencies to otherwise over plan and overpay. Driven by experience, we are very confident in our ability to meet our customer’s needs, so we often offer to start with a 20 to 40-hour block of time to meet with our team and when things go well, we move forward incrementally—removing the need to sign large contracts. This is a win-win scenario as it allows our customers to get comfortable with us without making a massive time or financial commitment and it allows us to have a very clear understanding of our customer’s goals and expectations. This is incredibly key to achieving success.

The Need for Speed… and Quality

We are committed to understanding our customer’s needs, and often their top priority is faster prototyping and iteration. We are uncompromising on quality and speed. But the need for speed doesn’t mean we forgo quality. We always ensure that quality is maintained and appropriate controls are in place for each stage whether it’s initial prototyping or production.

We take quality very seriously and as an ISO certified manufacturer of human-use products, we always maintain the highest standards required for the project stage.

Meeting the Demand Where It Lives

Many larger contract manufacturing companies tend to sort their customers based on the bottom line–the dollars they are bringing to the table. We’re trying to meet the needs of all of our customers–even the smallest ones. We have found that there is a pent up demand in this category–that we are quickly able to meet. This approach has allowed us, in some areas of our business to double or even triple our capacity.

We can often bring the resources the customer needs to the project reducing overall project cost, engineering, testing, quality, manufacturing, and distribution.

Customer service is a top priority. We strive to understand the needs of our customers and continually meet those needs. Our staff is always ready to talk to our customers about their projects and we consider good communication a core attribute of NPX.

NPX: A Division of Nextern

We have joined forces with Nextern to further improve the medical device development of our partners.

Nextern leverages world-class resources to offer robust research, development and manufacturing capabilities that will move your medical device project forward.