Medical device contract manufacturing is an exciting field to work in and our team of in-house engineers are pleased to serve our customers with more than 30 years of industry experience in engineering consulting.

We provide our insights and subject matter expertise to help you through the complete design and development process. We work to create a very specific plan with the commercialization of your product in mind from start to finish.

From first inception to final product, we will walk with you every step of the way. We can illuminate a clear path to achieving the goals and outcomes you have in mind. Let our experts show you the way.

Bringing Your Concept to Market

When a customer comes to us with a vision for a new medical device, we take as much time as necessary to understand their initial concept and design inputs. We help them define the clinical need, clarify the proposed solution, and thoroughly refine the requirements. From there, we put together a detailed proposal.

It’s common to see consultants want to go straight to making a prototype without investing the time to define exactly what the clinical need is, what all the potential solutions are, and what design alternatives may exist. These first steps are vital.

Having guidance from experienced professionals with expertise in developing similar products as well as knowledge in numerous specialties makes all the difference in making your idea a reality.

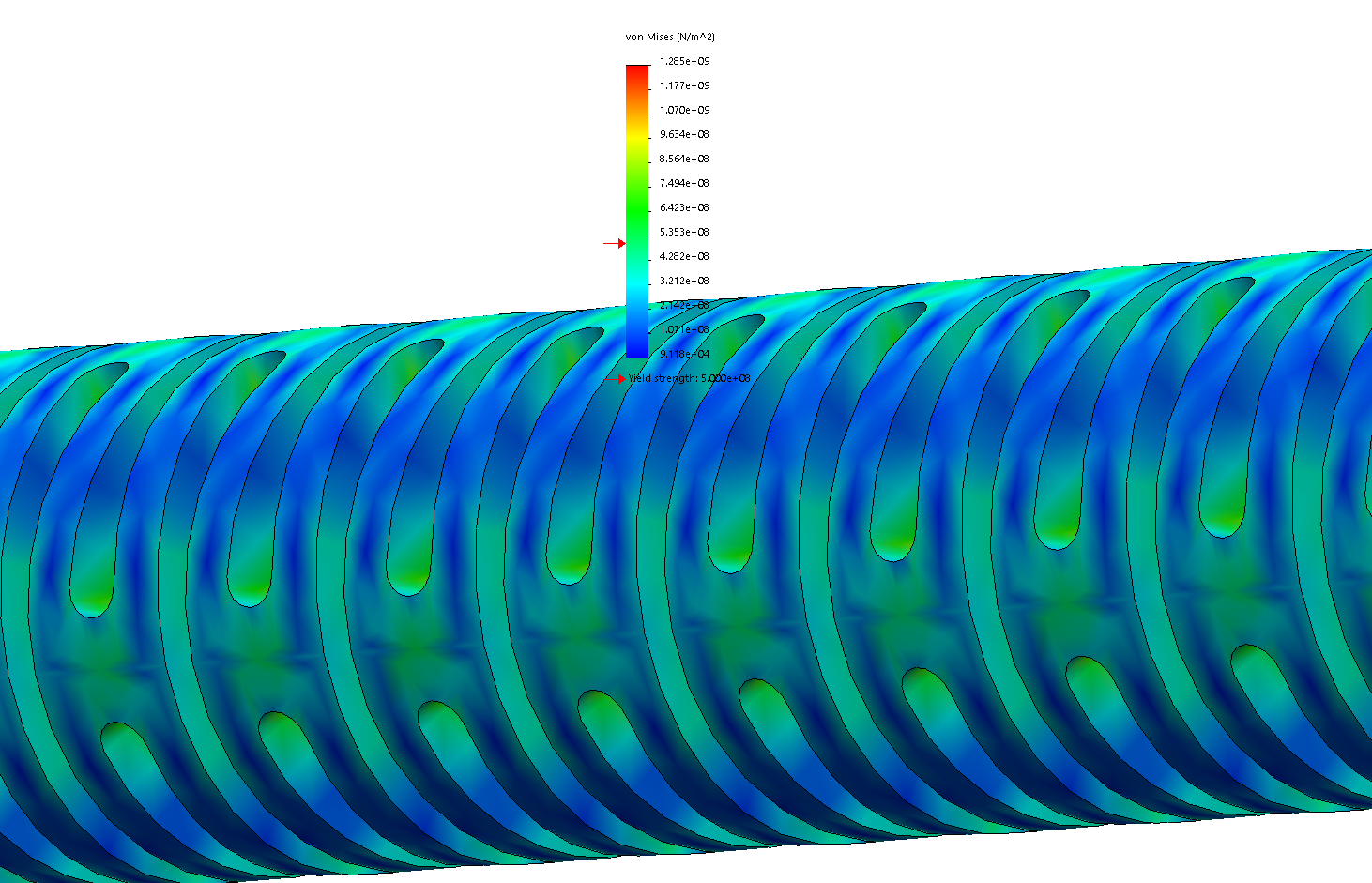

Our team has extensive experience in working with metals and polymers. The material that we recommend will depend on the clinical need and function that the engineering team determines. We will consider the mechanical requirements in the body, how the implant will interface with tissue or bone, and the functionality required for the implant procedure.

For instance, for an implant in an orthopedic application that’s continuing to impart force, we typically recommend nitinol or something similar. For other orthopedic applications, stainless steel may be a better choice.

Whatever the best fit for your project, our expertise in many different materials can help make your project a success.

Many of our competitors have long production lead times, making it difficult to iterate in a timely manner.

If you can prototype and iterate rapidly, you can move from the concept to a benchtop model in weeks instead of months.

Rapid prototyping allows you to refine your understanding of how the design solution can meet the clinical need. Because of our short lead times and expertise, we can typically iterate much faster than other development houses helping you get to market quickly.