New medical devices are always in the works. The biomedical industry is evolving in ways that are increasingly focused on optimizing healthcare and holistically improving the patient experience. For example, reducing the invasion and lingering effects of invasive surgeries and procedures is hugely beneficial for patients and doctors alike.

Achieving this kind of success depends on top biomedical engineers and developers. Medical device design aligns with biomedical necessity to keep the patient in mind, while simultaneously collaborating with engineers who can ensure the practical components and affordability of new medical devices. When end goals are aligned among everyone involved in new medical device design, the patient experience is improved.

What Is Medical Device Design?

Effective medical device design always keeps patients and end-users in mind. The purpose of creating new medical devices is to improve on existing instruments or to find solutions for current problems caregivers and patients are experiencing. Given this, biomedical devices require extensive research and understanding of the final goal before undergoing design and development.

Medical device design requires teams of researchers, UX/UI specialists, engineers, and sometimes patients and doctors to finalize a project outline. Biocompatibility and ease of use are two significant considerations during the early design stages as well. The materials used in new medical devices must be compatible with patient use, especially if the device will be implanted or will otherwise interact with the skin of the patient. Once the usability and biocompatibility are set, the medical device design can be sent off for development.

Examples of Medical Device Design

It is easy to talk about medical device design at a high level, but what does medical device design look like? There are always improvements to existing instruments as well as new biomedical devices being developed and introduced to patients and doctors every year.

For example, the Minneapolis-based manufacturing company 3M recently announced a new innovative adhesive that will benefit patients who need wearable medical devices. Sensors such as insulin pumps, continuous glucose monitors and patches require reliable adhesives to effectively operate. These adhesives can potentially cause harm to the skin, or they may not last as long and require more frequent changing. With the new adhesive from 3M, patients will directly benefit from skin-friendly, longer-lasting wearable devices.

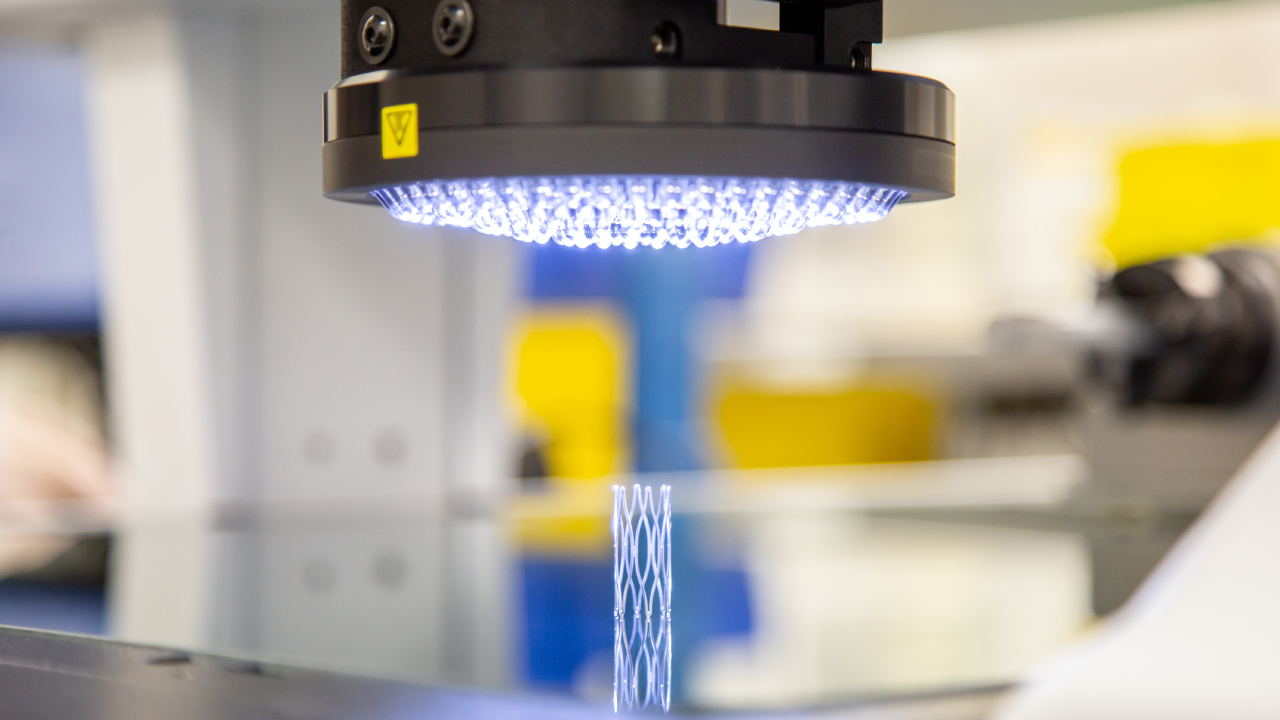

Additionally, other instruments that surgeons or doctors use are also being improved. Intravenous instruments, implants and needles are used every day in hospitals and clinics. Softer materials have been incorporated to make the use of these instruments safer, sharper and simultaneously less painful and invasive for patients.

What It Takes To Bring Your Idea to Market

Bringing new biomedical devices to market takes years to achieve. Medical device design is a months-long or even years-long process to ensure the proper materials, design and solution are considered and optimized. After the design, prototypes and testing are conducted. Finally, you can bring your new medical device to patients and doctors around the world.

Partnering with an experienced, local medical device manufacturing company can streamline your next biomedical device design and bring your ideas to life. The engineering team at NPX has extensive experience working with biocompatible materials, such as metal alloys and processes that ensure the highest quality and durability.

If you want to start your next medical device design, contact our team.