Braiding is the intertwining of metal wire to form a flexible tube structure.

Braids have been used in implantable medical devices as well as in catheters. In catheters, the braid reinforces the catheter shaft and can provide a variety of different desired characteristics including kink resistance, pushability, torquability, and hoop strength.

These characteristics can be manipulated from the braid material, braid wire dimensions, braid pattern, and braid pitch.

Braids can be done by a braider with multiple carriers to braid wire onto cores/mandrels or by operators. There are advantages and disadvantages to both.

Machine Braided

Machined braids can be used for the construction of many different catheters. Braiders for catheters typically use 16 carrier or 32 carrier braiders. The number of carriers is the number of wires that can be used in the braid construction. There are multiple braid patterns.

Typical braid patterns:

Full Load Braid

This configuration operates at 100% capacity of the braider. One single wire goes under two cross wires then over two cross wires. This is typically used for flexibility, pushability, and braiding speed.

Diamond Braid

This configuration has two wires going under two cross wires then over two cross wires. This is typically used for catheters that need good torqueability, kink resistance. Typically neighboring round wires are used for this configuration.

Half Load Braid

This configuration operates at 50% capacity of the braider. One single wire goes under one cross wire and the under one cross wire. This is the easiest braid to remove from cores. Typically flat wire is used for this configuration.

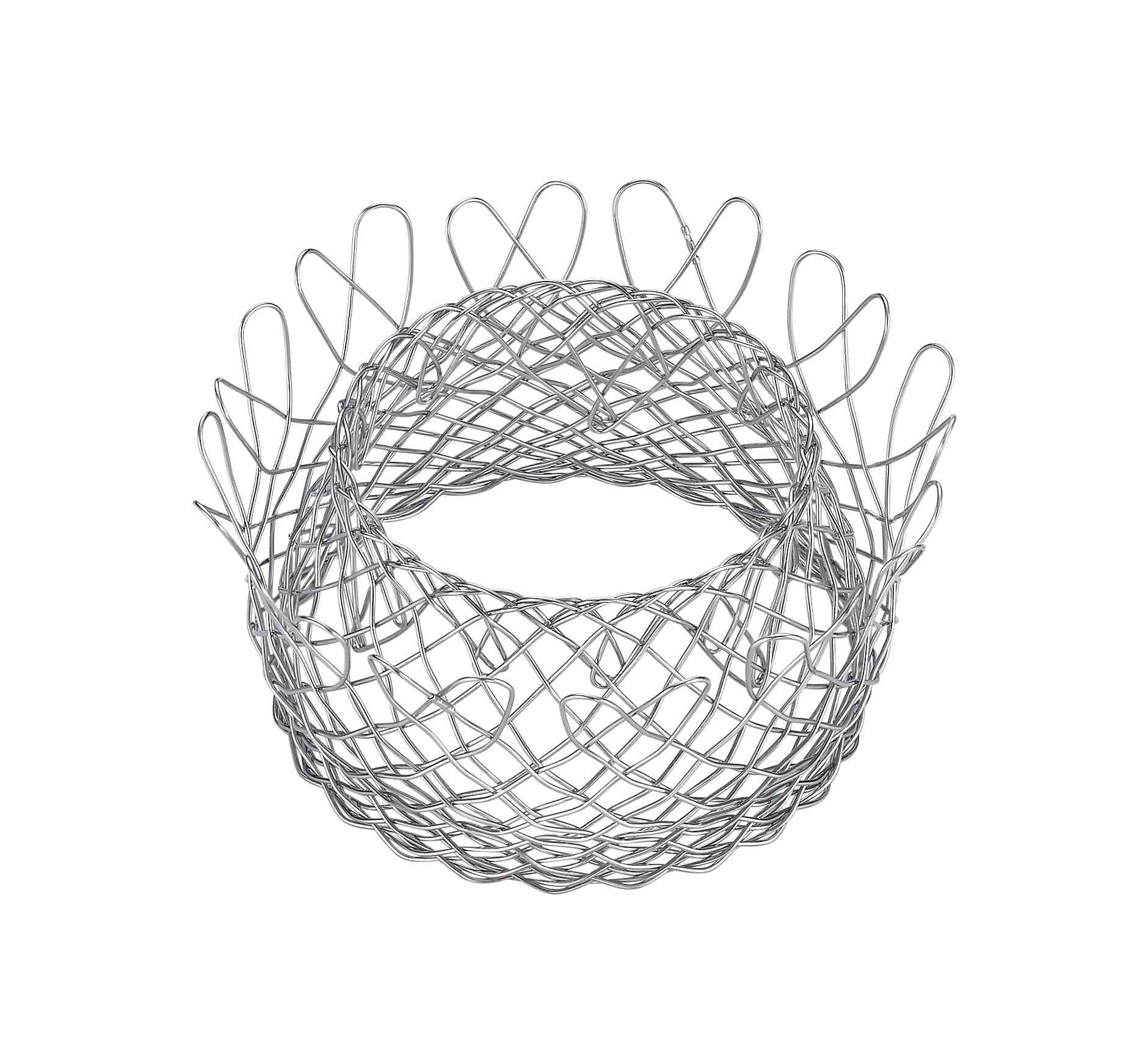

Hand Braided

Operators wrap and weave wire on mandrels to form different design. There is advantageous in the early stages of developing a nitinol stent or basket. Typically, 1 to 2 wires are used for a hand-braided part. This can make the termination simpler with fewer loose ends that need to be managed.