Manufacturing Stainless Steel Medical Devices

Stainless steel is a group of iron-based alloys containing the chemical element chromium, which prevents the iron from rusting, and also provides heat-resistant properties. Many types of stainless steel with different functionalities and properties can be produced with the introduction of different elements like carbon, nitrogen, aluminum, etc. Those specific types of stainless steel produced are often designated by a three-digit number.

Austenitic 304 and 316 stainless steels are considered surgical or medical-grade stainless steels and are the most commonly-used for laser-cutting. 304 is the stainless steel most utilized in NPX Medical’s medical device engineering and manufacturing because of the wide range of hardness levels it can achieve.

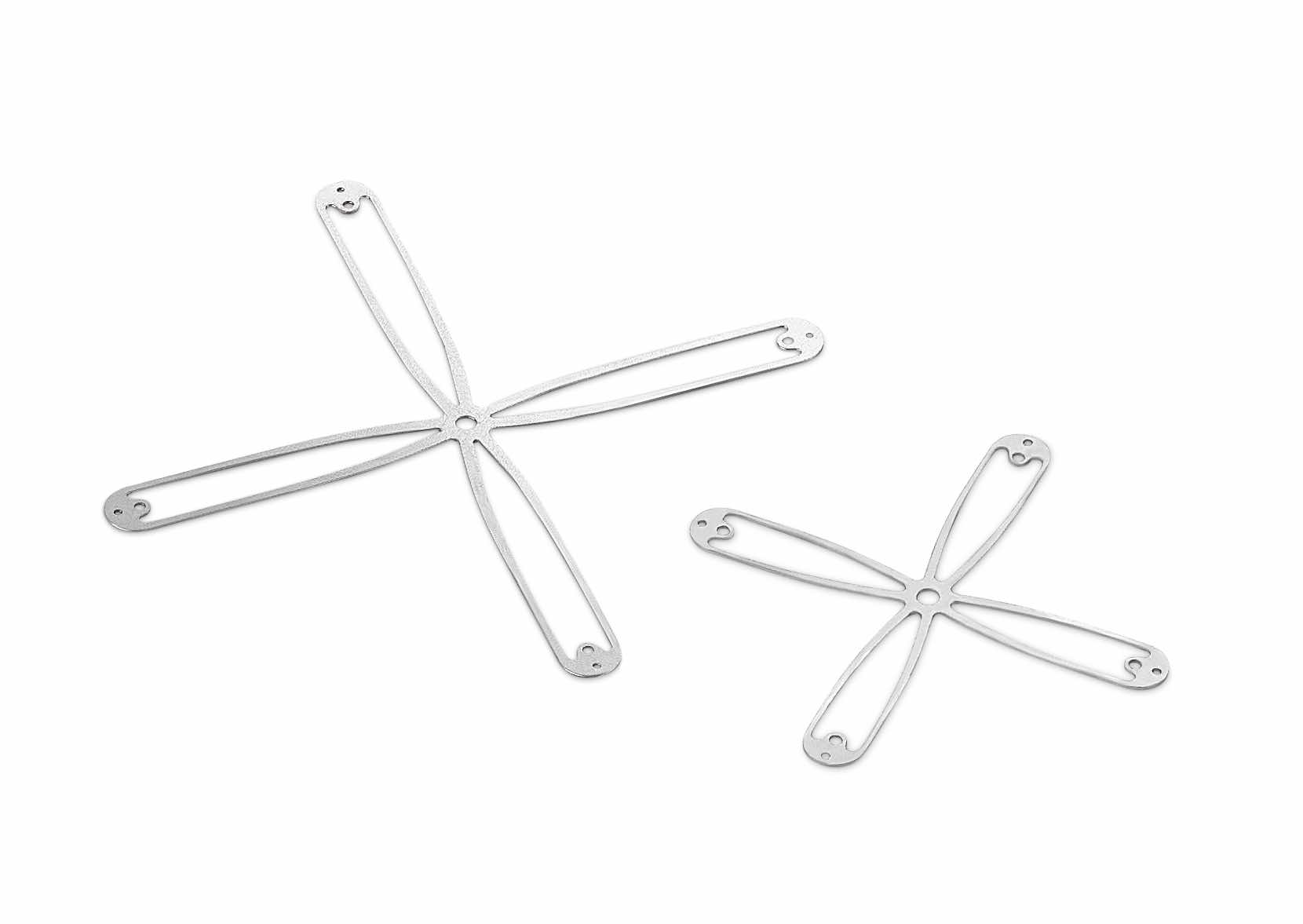

What are some of the most common medical devices that NPX Medical manufactures using stainless steel?

NPX Medical uses stainless steel to manufacture many of the components used in catheters. These catheters can be laser cut to have varying degrees of flexibility for steerable catheters to stiff delivery systems used in applications like orthopedics. Additionally, stainless steel can be found in assembly components and implants.

What makes stainless steel a well-suited material to be used for certain types of manufactured medical equipment?

Stainless steel is a very affordable material, particularly when compared to Nitinol – another alloy used in the medical device industry. Additionally, there are large stock lists of different size languages for stainless steel, which makes the material readily available and fairly quick to acquire. Stainless steel is a strong, tried-and-true material that can be laser cut and heat-treated for manufacturing purposes.

Overall, there is a considerable general awareness of stainless steel and its properties and uses.

What are some post-processing/surface finish options with stainless steel?

To achieve different surface finishes, stainless steel can undergo a chemical clean or can be grit blasted, chemically polished, chemically etched or electropolished, which typically yields the best results.

Electropolishing stainless steel is a reverse plating process that uses an electrochemical solution to remove the outer surface layer of the stainless steel. The process removes contaminants and improves corrosion resistance.

Nearly all NPX Medical’s stainless steel manufactured components undergo post-processing/surface finishing. Approximately 25% undergo a combination of grit blasting and/or electropolishing.

What are some characteristics of potential medical devices that would not make them ideal candidates for using stainless steel?

Generally, stainless steel is a strain-limited material. Different types of stainless steel can withstand varying levels of strain, but most 304 and 316 stainless steels do not withstand higher percent strains.

Devices requiring a really strong stainless steel that can resist bending will need to be manufactured with a full hard stainless steel or some other material. Equipment that is more ductile and will be used under higher strain conditions may require annealed stainless.