Manufacturing Titanium Medical Devices

Titanium is a natural metallic element – Ti on the Periodic Table – and is the ninth most abundant element in the earth’s crust.

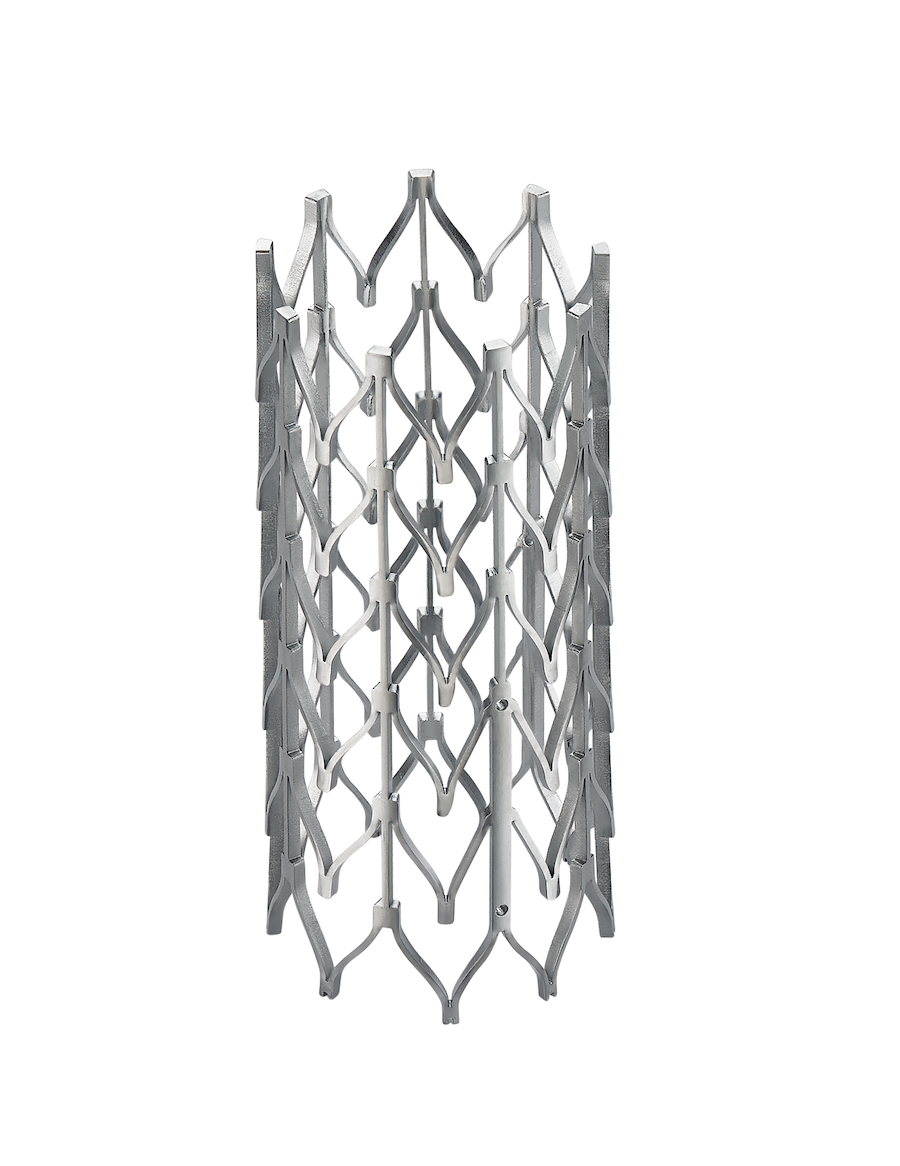

Titanium’s metallurgical characteristics make it a choice metal for an array of applications including, but not limited to, medical, aerospace, and consumer goods. Titanium is corrosion and erosion-resistant, non-magnetic, has the highest strength-to-weight ratio of all known metals, and holds its strength in high temperatures.

Additionally, titanium is a biocompatible material, meaning it is not harmful to living tissue and is therefore often favored in medical applications such as orthopedics and dentistry, among others.

What makes titanium such an attractive material for orthopedic applications?

Besides the biocompatibility, the stiffness of titanium is naturally closer to the stiffness of human bone than other stainless materials.

Titanium also does not hinder healing like many other materials can because of its titanium oxide layer. When exposed to oxygen, titanium creates a layer of ceramic-like oxide film that essentially protects itself from corrosion. This characteristic of Titanium promotes the in-growth of the material into the body rather than negating it.

Titanium is non-toxic, with little-to-no nickel present, and is not typically rejected by the body.

Additionally, Titanium is a paramagnetic material with very weak polar attraction and, therefore, MRI compatible.

When would Titanium be welded to Nitinol (Nickel Titanium)?

When welding is involved in the production of a Nitinol component or assembly, titanium can either be used as a substitute for Nitinol for higher formability, decreased heat dependency, and increased strength, or titanium can be used in conjunction with Nitinol to increase tensile strength.

Both Nitinol and Titanium have the same oxide layer, which increases the corrosion resistance of the welded components.

What are some benefits to using Titanium in manufacturing?

Titanium is both manufacturing-friendly and user-friendly. It is a strong material that requires little to no post-processing and is available in an array of quality grades.

Additionally, welding won’t change the mechanical characteristics of titanium—unlike nitinol which depends directly on heat setting at a specific temperature. Welding nitinol can compromise its shape memory, altering its mechanical characteristics. Titanium is not susceptible to this problem.

When manufacturing a device or components, what characteristics would not make it a good candidate for using titanium?

Titanium is a more expensive material than most other stainless metals or alloys. Titanium is also not as readily available in certain stock sizes and quality grades as stainless steel.